Process Control & Recycling

Olnica Material Traceability

Take Control of your Process, your Quality, your Recycling

The right material, in the right quantity, at the right place

The OLNITAG range has been designed to be incorporated in many types of materials:

- Solid materials like polymers, elastomers…

- Fluid materials like paint, resins… When dealing with processes involving several types of material, tracing materials thanks to the embedded taggant technology allows a precise control of the processes

Producers have the possibility to verify that the proper material has been applied at a specific place (specialized paint, coating), and that no area is left uncovered. In blend processes the “Olnica Dilution Control” application can not only verify the presence of a given component, but also quantify its quantity.

This is particularly effective in processes involving the incorporation of recycled materials. After production and during the whole life cycle of the product the quantity of recycled material incorporated can be measured and proven.

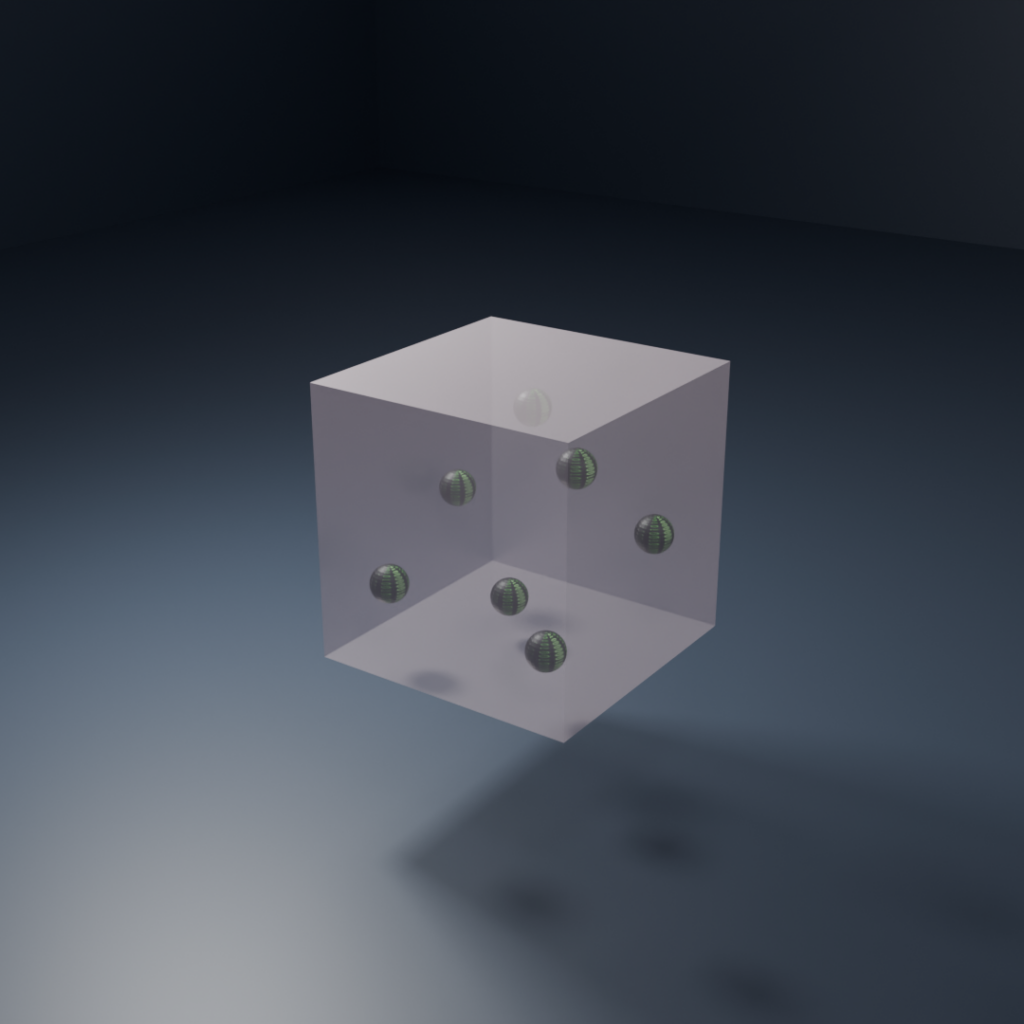

OLNITAG: Taggant with code encapsulation

OLNITAG Taggants are not just a chemical molecule that can be detected, like most chemical taggant existing on the market. They are produced with the patented technology allowing to incorporate a molecular code inside a polymer. This means that any taggant has the same unique code.

In case of a blend of several tagged materials , the taggant won’t blend or dilute each other.

Each individual taggant will remain as a specific cristal, thus allowing to identify the presence of each and every material.

Authenticate and Dilution Control

The detection technology of Olnica revolves around two pillars :

- Authenticate application: is the original identification detection technology that can identify a specific code.

Thanks to Olnica Authenticate application, you are sure this is the right material being used - Dilution Control: uses the quantification of the taggant present, to quantify the presence of the tagged material. You are sure the material is present in the right quantity.

Both detection technologies can be used either in inspection control with Olnica Pocket Lab, but also within production line control.

Use cases

Protection foil against erosion

An example of process and quality control optimisation can be found with the tagging of paints and coating.

On various foils in the aviation, or wind turbine industries, the leading edge coating is specifically designed to withstand erosion from liquid and solid particles. Thanks to taggant incorporation, it is easy to ensure that the specific anti-erosion coating has been used on the foil leading edge. During the lifetime of the foil, damage or attrition of the coating can be detected by the absence of response to the taggant detection.

Close loop recycling

Once a product has been tagged, when collecting material for close loop recycling, Authenticate application allows a verification that the return material is indeed the proprietary material.

Once incorporated in the new production loop, the tagged recycled material can be identified, and quantified with “Olnica Dilution Control”.

This recycling percentage identification can be used for regulatory reasons, but also to ensure that final product properties will not be negatively impacted.

Why choose Olnica?

- Patented, proven technology: our unique taggants offer an unrivalled solution for authentication and traceability.

- Recognized expertise: for years, we have been helping the most demanding industries meet their traceability and compliance challenges.

- Adaptability: our solutions integrate easily into your existing processes, without disrupting your operations.

- Quality commitment: our technologies meet the highest standards, guaranteeing reliability and precision.